Established processes and chemicals taking care of the environment

Eco challenges in Beamhouse and Tanning

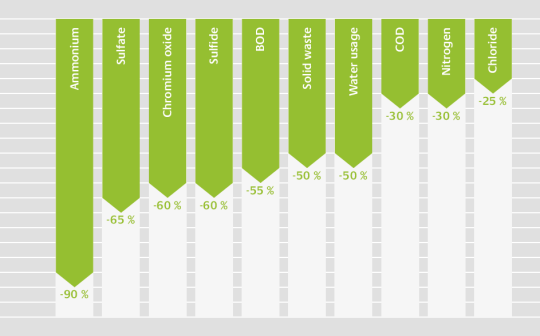

The main challenges in processing raw hides and skins are high contents of sulfide, nitrogen, salts and chromium and too high COD / BOD values of the waste water. In addition there are obnoxious smells, solid waste and fresh water consumption to deal with.

TFL ECO TEC in Beamhouse

Soaking / Liming – Low sulfide unhairing:

The TFL low sulfide unhairing provides a clean, relaxed, well opened-up pelt by using:

- PELLVIT® LSG or PELLVIT® LSS in soaking to clean the hair and hair follicles from grease to avoid hair root retention

- ERHAVIT® LSU to support the unhairing process and allowing to reduce the lime and sulfide offer

- BORRON® DLS to avoid fat smearing drum wall and pelt

Deliming / bating – Ammonium-free deliming / bating:

A safe, buffered system which cleans the pelt remarkably well without having a negative effect on the integrity of bellies and grain by using:

- DERMASCAL CD, ammonium free deliming agent

- OROPON® ON2, OROPON® W, OROPON® MS, OROPON® MT, ammonium free bating agents

- BORRON® SCA bleaches and boosts scudd removal

Benefits:

- Sulfide reduction

- COD / BOD reduction

- Odour reduction

Sludge reduction in case hair is filtered - Ammonium and total nitrogen reduction

- Risk reduction of H2S gas formation

- Energy reduction in waste water treatment plant

- Optimised hair and scutt removal

- Lay-out improvement

- Optimal cutting yield

TFL ECO TEC in Tanning

Pickling / Chrome tanning – Low salt pickling:

A fine grain wet blue with reduced offer of chromium and common salt can be produced with:

- SELLATAN® PA Liq as a pickle acid which allows a more even chromium penetration and improved chromium exhaustion

Benefits:

- Sulfate and chloride reduction

- Chromium reduction

- Better chrome distribution

- Finer grain

- Improved leather quality

TFL ECO TEC – we help you to significantly reduce your water usage

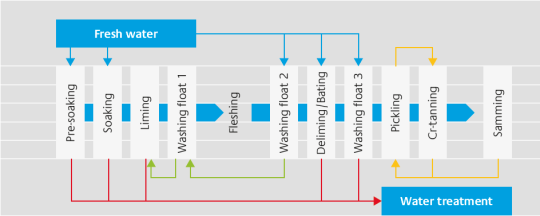

Direct float recycling:

- Pre-soaking, main-soaking, the washing before deliming and after bating are all done with fresh water

- The washing float from before deliming is re-used as washing float after liming and this float is re-used as liming float

- Pickle and tanning floats are recycled in a closed loop

- Pre-soaking, main-soaking, liming, deliming and the washing floats after bating are discarded as waste water

Main Reaction - The TFL Blog Stories, incidents, tips and facts around the topics leather, chemistry, fashion, sustainability and ecology. Our editorial staff consisting of experienced tanners, scientists, market experts, fashion and communication specialists has sharped their pencils and will supply you with fresh and inspiring content on a regular basis.

Main Reaction - The TFL Blog Stories, incidents, tips and facts around the topics leather, chemistry, fashion, sustainability and ecology. Our editorial staff consisting of experienced tanners, scientists, market experts, fashion and communication specialists has sharped their pencils and will supply you with fresh and inspiring content on a regular basis.

LEVOTAN® / LUBRITANTM - Looking for higher performance? Tanners around the world are facing increasing challenges from their customers, for example, demands for higher performance such as fastness to light and heat resistance, but also lighter weight leather and more recently odour / emissions avoidance.

LEVOTAN® / LUBRITANTM - Looking for higher performance? Tanners around the world are facing increasing challenges from their customers, for example, demands for higher performance such as fastness to light and heat resistance, but also lighter weight leather and more recently odour / emissions avoidance.