TANIGAN®

BPS/BPF optimized Syntans

Addressing the very latest regulatory challenges

The Background

TFL is a leading global manufacturer and supplier of high quality syntans that are recognized worldwide with the famous brand names of SELLATAN® and TANIGAN®.

To maintain this lead TFL continually invest in pioneering research, development and extensive application support to keep you at the cutting edge of the very latest technological advances.

ECHA has published the restriction draft on bisphenol A and other bisphenols of similar Concern (BPA and BosC; including BPS/BPF) and now the consultation phase begins for a minimum of 12 months. After finalization the restriction draft foresees that other (non-leather) industries using bisphenols will need to reduce BPA and BosC traces to 10 mg/kg or less within 18 months (2025 earliest) while leather will have an additional 5 years at 500 mg/kg or less (to 2030). There are a few points in the restriction draft that will need further clarification and TFL together with key partners will follow up on those topics and keep customers updated.

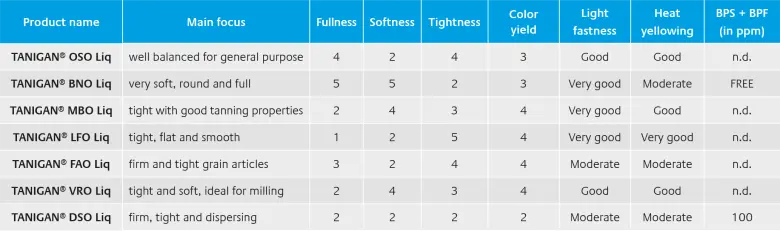

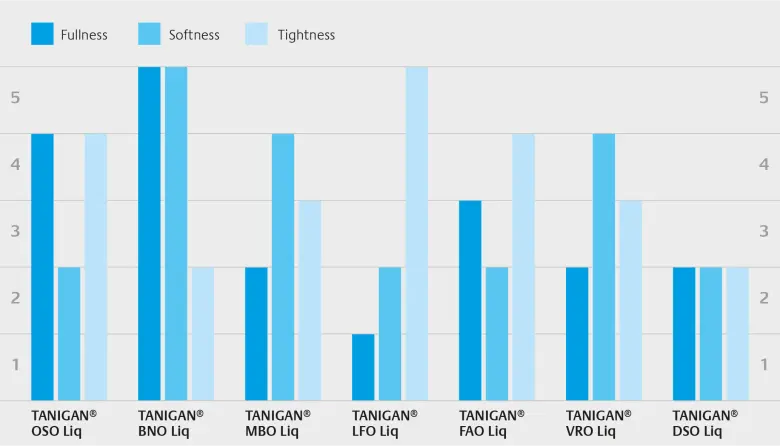

TFL, as a global leader in chemicals for leather production, had immediately started to develop products to address this new challenge once it became public. TFL has already launched an indispensable range of genuine syntans that enable customers to manufacture leathers that will comply to upcoming threshold of 500 mg/kgof bisphenols, all developed, manufactured andstrictly controlled within TFL’s own facilities. This invaluable new range of syntans facilitate the production of the vast majority of leather articles and ensure the required leather properties and fastnesses are attained. This new range includes:

TANIGAN® BN-O Liq, TANIGAN® LF-O Liq, TANIGAN® RL-O Liq, TANIGAN® DS-O Liq, TANIGAN® FA-O Liq, TANIGAN® VR-O Liq and TANIGAN® MB-O Liq.

Now we launch in addition TANIGAN® MB-O Liq with a combined BPS + BPF content of less than 20ppm, below the detection limit (not detectable). This “next generation” ultra-low bisphenol content replacement syntan can be used together with the above syntans in combination to achieve the leather properties and performance required and more easily stay within the restriction limit.

Thanks to this experience and competence TFL is particularly well positioned to continue successful research to ensure customers can also meet any future regulatory requirements with their processes and articles.

Please keep in mind that the vast majority of TFL’s comprehensive wet end retanning products portfolio is completely free of BPS and BPF under the following well-known trade names: RETINGAN®, MAGNOPAL®, LEVOTAN®, BLANCOROL®, TANNESCO®, DRYWALK®, LEUKOTAN™, LUBRITAN™ (and most of SELLASOL®) of course along with all TFL fatliquors and dyestuffs etc.

Main Reaction - The TFL Blog Stories, incidents, tips and facts around the topics leather, chemistry, fashion, sustainability and ecology. Our editorial staff consisting of experienced tanners, scientists, market experts, fashion and communication specialists has sharped their pencils and will supply you with fresh and inspiring content on a regular basis.

Main Reaction - The TFL Blog Stories, incidents, tips and facts around the topics leather, chemistry, fashion, sustainability and ecology. Our editorial staff consisting of experienced tanners, scientists, market experts, fashion and communication specialists has sharped their pencils and will supply you with fresh and inspiring content on a regular basis.

LEVOTAN® / LUBRITANTM - Looking for higher performance? Tanners around the world are facing increasing challenges from their customers, for example, demands for higher performance such as fastness to light and heat resistance, but also lighter weight leather and more recently odour / emissions avoidance.

LEVOTAN® / LUBRITANTM - Looking for higher performance? Tanners around the world are facing increasing challenges from their customers, for example, demands for higher performance such as fastness to light and heat resistance, but also lighter weight leather and more recently odour / emissions avoidance.