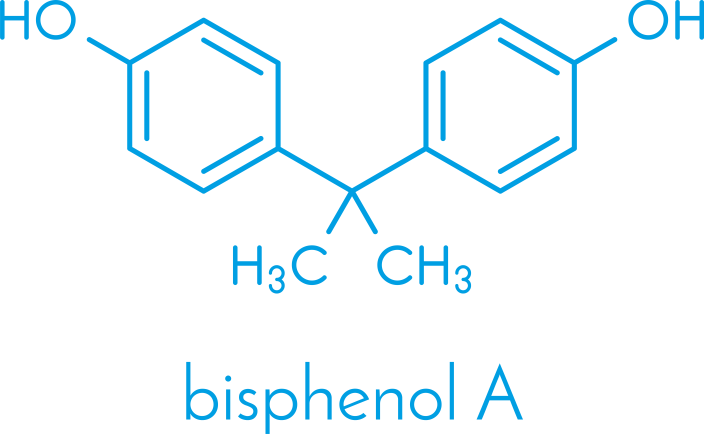

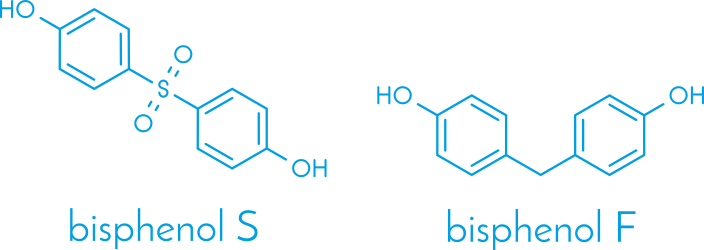

What are Bisphenols?

The Federal Office for Chemicals (BfC), the German authority for REACH, has proposed to restrict Bisphenols with endocrine disrupting properties for the environment. Bisphenols are a group of man-made chemicals that are used in the manufacturing of polycarbonate plastics and epoxy resins. The most widely used chemical in the group, produced in high volumes, is Bisphenol A (BPA).

The use of the other Bisphenols, such as Bisphenol S (BPS) and Bisphenol F (BPF) is limited in comparison. However, these chemicals are relevant in leather making and are recognised as Bisphenols of Similar Concern (BoSC).

Restriction of Bisphenols in Leather

EU Regulation of Bisphenols

The restriction draft of ECHA on Bisphenol A and other Bisphenols of Similar Concern (BoSC) foresaw for leather a limit of 500 mg/kg BPS/BPF by 2025 and reducing further this limit to 10 mg/kg by 2030, has changed. The Federal Office for Chemicals (BfC), the German authority for REACH, has decided to temporarily withdraw the dossier without further information. It is therefore likely that the implementation of the restriction will be delayed by ca. 18 months, and it is not yet clear whether the conditions will remain the same. However, based on all facts that ECHA have published in this context, there is currently no reason to believe that conditions for the leather application will significantly improve.

The temporary lifting of the restriction does not have any impact on other Bisphenol regulations:

- Syntans containing > 0.3 % BPS will be labelled as reprotoxic for fertility, category 1B (no later than 01.12.2023)

- Syntans containing > 0.1 % BPS will be mentioned in chapter 3 of the MSDS (already in place).

- BPS included in the SVHC candidate list (import of leather to be notified to ECHA if > 0.1 % and >1 t/article of BPS combined).

USA Regulation of Bisphenols “Proposition 65”

The news about the temporary withdrawal of the dossier, by The Federal Office for Chemicals (BfC), the German authority for REACH, concerning the restriction draft of ECHA on Bisphenol A and other bisphenols of similar concern (BoSC) has rapidly spread in the tanning community.

Whilst this initially seems like good news it has unfortunately lured some into a very dangerous false sense of security. The reality is that this draft is only delayed plus famous brands have either already implemented or currently implementing the addition of bisphenols to their own “Restricted Substances Lists” (RSL’s).

Unfortunately, in addition we now must advise you that in the USA, Bisphenol S (BPS) has been listed as a “reproductive toxicant” under “California Proposition 65” (Prop 65). The warning requirement for significant exposure to BPS of leather consumer articles will take effect on December 2024. It is yet, however, unclear how “significant exposure” will be defined in the USA. The Prop 65 listing requires that all consumers buying an article made of leather, whether a shoe, handbag, car seat or sofa etc., are informed that it contains BPS, that is/are known to the State of California to cause birth defects or other reproductive harm together with a link to the government website.

We at TFL are in close contact with the US authorities and will keep you fully informed of all developments in this field as soon as they become available to support you and your work to success.

CONCLUSION

The best possible way to ensure compliance to these legislative and brand challenges is to adopt TFL’s newly launched seven ultra-low to zero bisphenol syntans namely, TANIGAN® OSO Liq, TANIGAN® BNO Liq, TANIGAN® MBO Liq, TANIGAN® LFO Liq, TANIGAN® FAO Liq, TANIGAN® VRO Liq and TANIGAN® DSO Liq that replace the major “icon” and well-positioned products and thus enable the vast variety of leather types and properties to be achieved. All have a bisphenol content below the detection limit (n.d. = non-detectable) or zero. The only exception being TANIGAN® DSO Liq with an ultra-low < 100 ppm bisphenol level. With these products you can produce leather below detection level (<10 ppm of bisphenols for the leather) and will be way ahead of any current or expected legislative restrictions!

es to inform consumers buying an article that this does contain BPS, like: “WARNING: This article can expose you to chemicals including BPS, which is/are known to the State of California to cause birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov .

It is yet unclear if “significant exposure” will be defined in the US as e.g. the 500ppm proposed in the draft of the REACH restriction. TFL will keep you updated with the very latest information as soon as it becomes available.

Brand RSL’s

Brands are independently implementing their own Restricted Substances Lists (RSL’s) not only in advance of any legislation, but the values can also be harsher, forcing the tanneries to comply with the low bisphenol limit in the leather supplied. TFL, as a global leader in chemicals for leather production, had immediately started to develop products to address this new challenge once it became public.

TFL Ultra-low to ZERO Bisphenol replacement syntans

TFL is a leading global manufacturer and supplier of high quality syntans that are recognized worldwide under the famous brand names of SELLATAN® and TANIGAN®.

To maintain this lead TFL continually invest in pioneering research, development and extensive application support to keep you at the cutting edge of the very latest technological advances.

Building on the leading SELLATAN® and TANIGAN® syntans global success, TFL now launches the next generation of ultra-low or zero BPS/BPF syntans, now unified under the single brand name TANIGAN®. By working together with these new TFL syntans you will be ahead of any current or expected legislative restrictions. These next generation products represent an indispensable new range of genuine replacement syntans that allows the production of leather below detection level (<10 ppm of bisphenols for the leather).

Please keep in mind that the vast majority of TFL’s comprehensive wetend retanning product portfolio is completely free of BPS and BPF under the following well-known trade names: RETINGAN®, MAGNOPAL®, LEVOTAN®, BLANCOROL®, TANNESCO®, DRYWALK®, LEUKOTANTM, LUBRITANTM, SELLASOL® and of course together with all TFL fatliquors and dyestuff ranges etc.

Do you need any further assistance? Get our expert advice.

Testing of Bisphenols in Leather

ISO 11936:2023 - Detection limit for bisphenols: 20 ppm for chemicals / 10ppm for leather.

TFL has already launched an indispensable range of genuine replacement syntans that enable customers to manufacture leathers below the detection limit (n.d.) all developed, manufactured and strictly controlled within TFL’s own production facilities.

- 1

TANIGAN® OSO Liq

Universal replacement syntan for a wide range of applications with well-balanced properties including good fullness and tightness together with dispersing effect

- ultra-low residual monomer content, including free formaldehyde and BPS / BPF (not detectable)

- treated leather has a good degree of whiteness, light fastness and heat yellowing resistance

- 2

TANIGAN® BNO Liq

The ideal replacement syntan for very soft and round leather with a high degree of filling and excellent tanning

- FREE of BPS / BPF

- ideal for milled leather

- 3

TANIGAN® MBO Liq

The ideal replacement syntan for soft and tight leather, equally suitable for white and due to high colour yield also dyed leather with brilliant shades.

- ultra-low residual monomer content, including free formaldehyde and BPS / BPF (not detectable)

- Its tanning power makes it extremely suitable for pretanning, tanning and retanning of wet white and retanning wet blue

- very good light fastness and good heat yellowing resistance

- 4

TANIGAN® LFO Liq

The ideal syntan for very tight, flat “not plumped” smooth grain leather articles

- ultra-low residual monomer content, including free formaldehyde and BPS / BPF (not detectable)

- high degree of whiteness with very good light fastness and heat yellowing resistance

- 5

TANIGAN® FAO Liq

The ideal replacement syntan for firm, compact and tight leather articles

- ultra-low residual monomer content, including free formaldehyde and BPS / BPF (not detectable)

- 49 % bio-content

- highly suitable for retanning waterproof articles e.g., military or “American lifestyle” type

- 6

TANIGAN® VRO Liq

The ideal replacement syntan for milled leather types combining a high degree of tightness and softness , ultra-low residual monomer content, including free formaldehyde and BPS / BPF (not detectable)

- 24 % bio-content

- good fastness to light and heat yellowing resistance thus recommended for automotive articles

- 7

TANIGAN® DSO Liq

Syntan with pronounced dispersing properties applied in combination with other syntans and vegetable tannins

- very low residual monomer content, including free formaldehyde and BPS / BPF (<0.01 %)

- treated leather is firm, with a fine tight grain due to low astringency, with full round handle

_in_the_reach_svhc_candidate_list.jpg_profilex2.jpg)